DAWSON DOWNIE LAMONT

Products from UK

Dawson Downie Lamont design and manufacture Reciprocating Pumps in accordance with API 674 and the Hydraulic Institute Standard for the oil & gas, petrochemical and marine industries worldwide.

Dawson Downie Lamont offers a comprehensive range of Direct Acting Steam/Gas Driven Reciprocating Pumps to suit the most arduous applications within the Oil, Petrochemical and Refining industries. Dawson Downie Lamont Steam Driven Pumps are designed, manufactured and tested in accordance with API 674 and the Hydraulic Institute Standards. Each pump is of a bespoke design to meet the required operating conditions.

Direct Acting Steam Driven Pumps:

Design Features

Direct Acting Steam Driven Pumps are suited for use in hazardous areas such as oil refineries, petrochemical plants etc. They are ideal for very arduous applications as these pumps operate at low speed to reduce wear and pressure pulsations. They are also most suited to applications involving high liquid temperatures and low available NPSH.

-

Self Priming

Solids Handling Capability

Powered by High Pressure, Medium Pressure, Low Pressure or process exhaust steam.

Intrinsically safe, most suitable for use in hazardous areas.

Suitable for pumping liquids of variable viscosity and temperature.

Variable Output from zero to maximum capacity.

Pumps available in a variety of materials to ensure compatibility with the pumping medium.

Disc Type Valves available for low NPSH requirements.

Designed is accordance with API 674 and the Hydraulic Institute.

Flanges to suit customer requirements.

Water cooled stuffing boxes are fitted for elevated pumping temperatures and process liquids with low specific gravity.

Steam jacketed liquid ends utilised for liquids with high viscosity.

DUPLEX CAP & VALVE

Suitable for a variety of general refinery process duties requiring low to medium discharge pressures.

Discharge Pressures up to 24 Bar, flow rates up 250 m3/hr.

DUPLEX & SINGLEX SIDE POT

Suitable for a variety of general refinery process duties requiring low to medium discharge pressures.

Discharge Pressures up to 24 Bar, flow rates up 250 m3/hr.

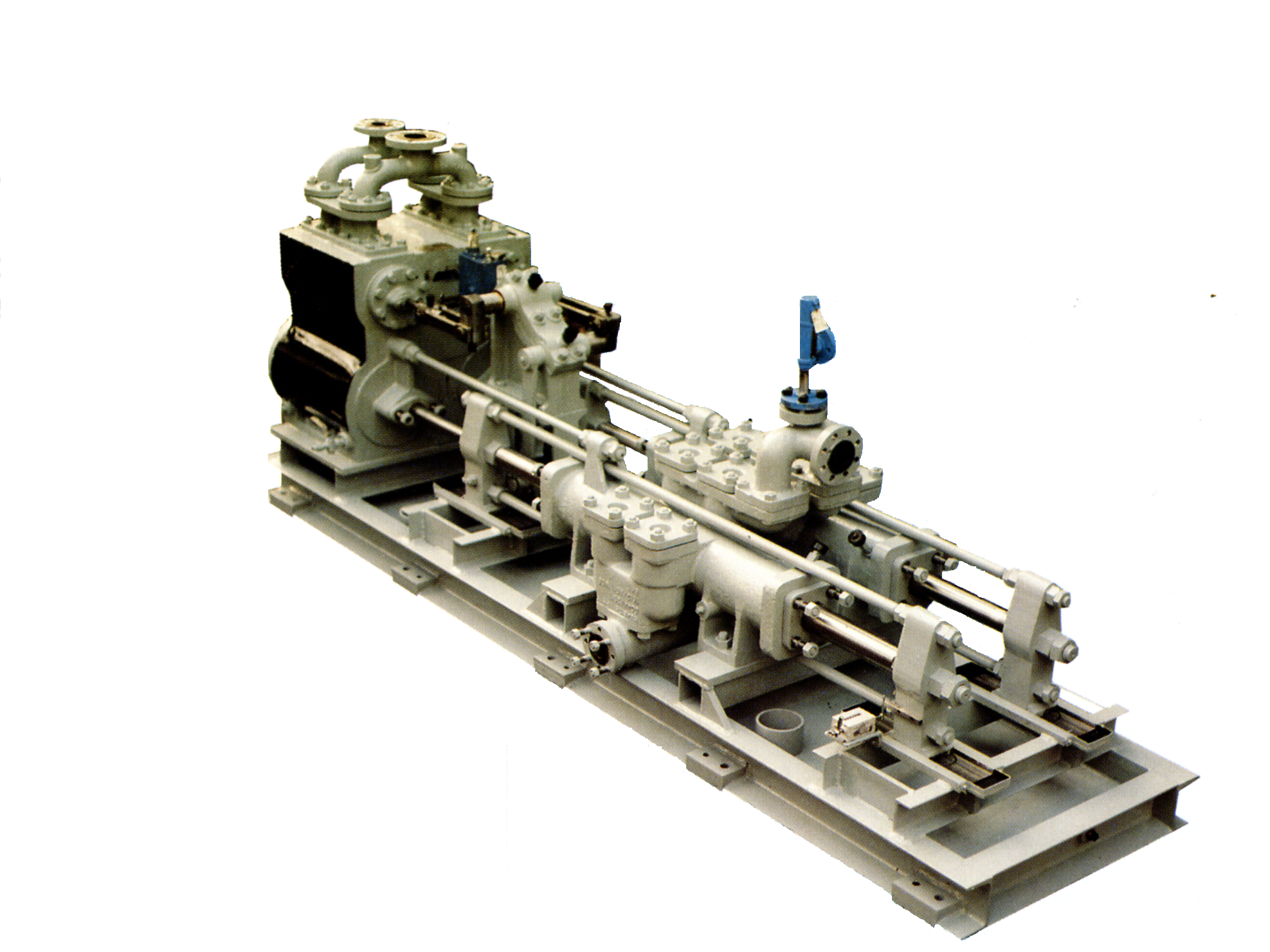

OUTSIDE RAM TYPE

Suitable for Hydraulic and High Pressure Injection service. Specially designed with suitable load ratio to generate high discharge pressure many times greater than the effective pressure of the motive Steam/Gas.

Discharge Pressure up to 172 Bar, flow rates up to 15m3/hr.

Dawson Downie Lamont Horizontal Triplex Power Pumps are designed, manufactured and tested in accordance with API 674 and the Hydraulic Institute Standards for high efficiency and high pressure hydraulic duties to give trouble-free service with minimum maintenance. Both design and dependability have been proved in thousands of hours of arduous operation throughout the world.

Horizontal Triplex Power Pumps

Design Features

-

Forged or cast steel fluid ends to suit the pressure and fluid are available in various material options to ensure compatibility with the pumping medium.

Totally enclosed crank-case, with improved splash-gravity lubrication provides for continuous running with minimum attention. For severe service a forced feed system is fitted.

Heavy duty taper roller Main Bearings rated for continuous duty cycle at maximum design load.

Hardened wearing parts in specially selected metals, with anti-friction bearings and bushes, mean long life.

Light-weight Disc Valves for low NPSH availability. Special Abrasion Resistant Valves incorporating Polyurethane inserts for use on highly abrasive duty applications.

Suction and Discharge Flange Nozzles to customers preferred rating standard. Handling of flanges to suit customers piping layout.

Pumps can be run at any fixed speed below the maximum depending on displacement required and the power source which can be electric motor or I.C. engine through

V-Rope, or gear drive.

Flow Rates up to 45m3/hr.

Pressure up to 400 Bar

Horizontal Triplex Motor Driven Plunger Pumps

Learn more about the company: