Bornemann

Product from Germany

Twin-Screw Pumps

Bornemann is a market-leading provider of Multiphase pumping systems for the oil and gas industry, and also serves the petrochemical / refinery, marine, chemical, and hygienic industries.

Twin screw pump, Design for API 676, Oil & gas, Refineries, Petrochemical, Hygienic application.

Bornemann Twin Screw Pumps are ideal for pumping mixtures of crude oil, gas, water and solids. They can be used in the upstream, midstream, and downstream industries. Dry running capabilities also allow the presence of gases. Compact design and special screw profiles allow high Δp for operation in pipelines with long distances.

Bornemann Twin-Screw Pumps are self-priming, double ended positive displacement pumps with external timing gears and bearings. Manufactured in over 80 sizes, their design provides complete axial balancing of the rotating elements and eliminates all metal-to-metal contact within the pump.

They can handle virtually any non-homogeneous fluid, regardless of viscosity, lubricity or abrasiveness e. g. seawater, bitumen, molasses, lime, acid, caustic solution or hydrocarbon.

Type W / V

-

Self-priming rotary displacement pumps in a compact range with external bearings without touching medium. For aggressive media also.

Type HC / VHC

-

This two-piece design also allows the screws and shafts to be replaced independently of one another, maximizing interchange ability while reducing maintenance cost and downtime. Shafts are made of high-quality stainless steel (DIN rating 1.4542, ANSI 630 S.S.) as standard equipment. The excellent physical properties and chemical resistance of this steel grade has been proven on thousands of Bornemann Pumps worldwide.

-

Wide range of applications

Self-priming

Pumped capacity proportional to speed

Compact construction

Direct drive without speed-reducer possible

Change of pumping direction - simple

Pumping elements - simple to replace

Easy maintenance

For almost all media and fluids

High viscosities possible

Low pulsations

Low noise level

Dry running possible

Constant flow on varying pressures and volumes

Very good suction performance up to NPSH 1 - 1,5 m/3 - 5 feet

-

Up- and Midstream

Downstream

Marine

Offshore

Industry

Food and Pharma

Type HP

-

The HP pump is designed with external bearings and timing gears lubricated with clean lube oil. External lube oil or cooling systems are not required what keeps the system as simple as possible and subsequently increases the reliability of the system.

Complete Pipeline Evacuation

Handling of some (minor) gas fractions

Type SLI Compact Pump

-

The pumped fluid flows through the screws in an axial direction. Therefore, the pump imparts very low shear and little pulsation to viscous and shear-sensitive products. For this reason, SLI pumps are well suited for fluids with high or low viscosity, with lubricating or non-lubricating properties, and fluids containing some solid.

Multiphase Boosting, Twin Screw Pumping Technology

INTELLIGENT UPSTREAM SYSTEMS FOR THE OIL AND GAS INDUSTRY

INCREASED OIL RECOVERY WITH MULTIPHASE TECHNOLOGY

-

The focus is on unpredictable flows, previously considered as unprofitable. Multiphase pumps handle these with ease and at a fraction of the conventional costs.

-

There is a Multiphase solution to suit a whole range of potential flows. Untreated products ranging from wet gas to heavy crude are pumped reliably in any situation – off-shore, subsea, thermal, conventional. In addition flaring can be avoided making this by product available for profitable use.

-

Exploiting oilfields in harsh environments and subsea. Extending the life of dying oilfields in this way is the perfect opportunity to generate a sizeable profit.

It is our job to make high-quality, cost-effective pumps and systems that provide outstanding benefits to our customers.

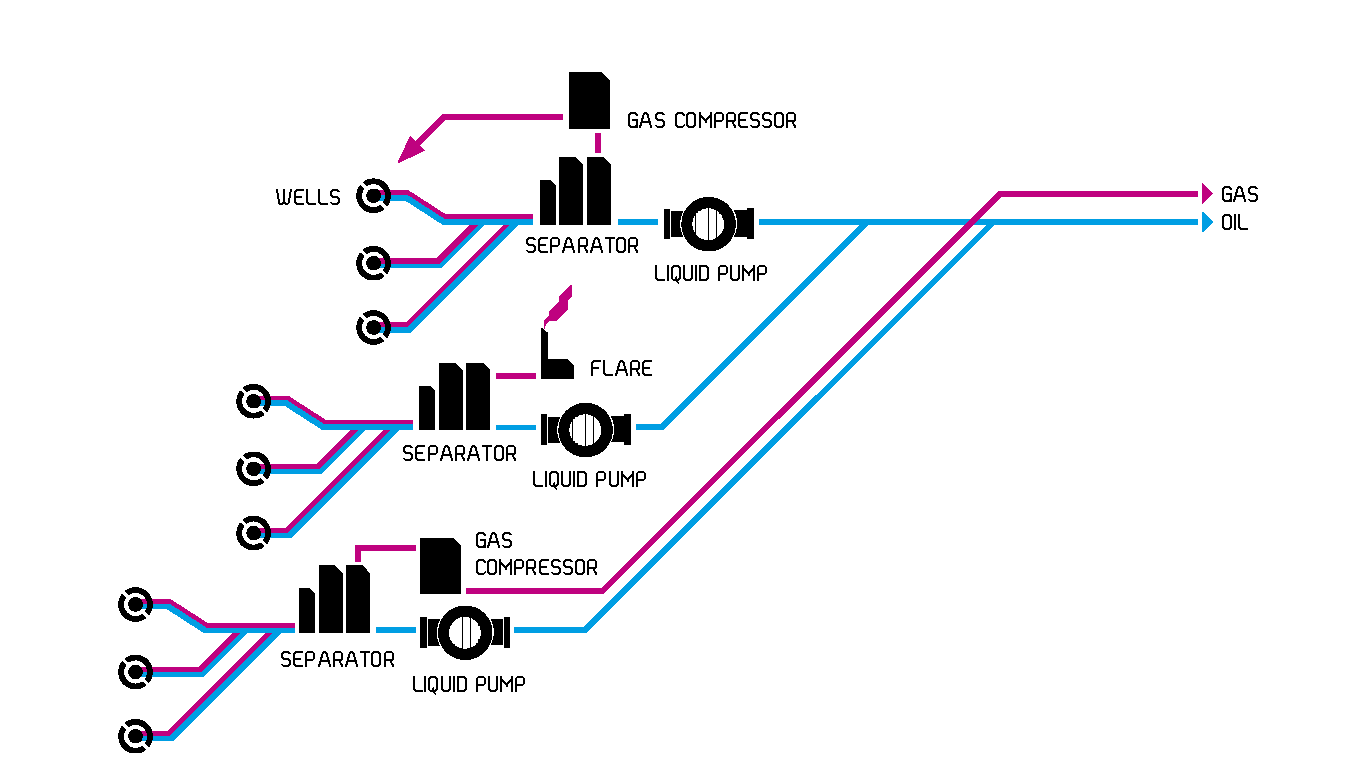

CONVENTIONAL STREAM

UNTREATED STREAM USING BORNEMANN MULTIPHASE TECHNOLOGY

-

Insert multiphase technology near or at the wellhead. Wonder in the know-ledge that the throughput of fluids, gases, solids and any mix is guaran-teed! Make the most of the conven-iently situated existing plant.

-

Construct the separators and processing plant on land where it best suites. Appreciate the refinement and open up the accessibility!

-

Multiphase offers cost savings almost everywhere. The only equipment necessary is delivered as a complete fully functional unit mounted on a skid. Consequently, engineering and installation are straightforward, and the construction period is shortened.

Coming on stream could not be easier. Just connect the well, Multiphase Unit, Pipeline and Power. The proven mechanical seal and system design guarantee that Multiphase will satisfy the most stringent environmental requirements and work under full safety without extra investment. The Multiphase compact design also requires much smaller land-based installations, resulting in a further saving.

-

A reduced maintenance program combined with a minimal on-site replacement part store results in further savings. The near maintenance-free installation ensures a reduced manpower requirement and coupled with the high reliability leads to virtually no outage. Keep the oil flowing and maximize your margins!

-

POLLUTION DOWN NEAR ZERO.

LAND REQUIREMENTS REDUCTED.

ENERGY SAVING.

-

Due to the unique Multiphase pump design there are no leakages of gas or liquid. The energy saved through the use of the previously flared gases is also a contribution to keeping our environment clean.

Separation at source requires costly multi-transport of the separated products. The Multiphase principle of transport before separation protects the environment by consuming considerably less energy and using less land. The gases previously flared off are now available e.g. for power generation, sales, gas injection.

Land-based projects: The same straightforward installation and cost savings apply. Whatever the situation – permafrost, desert, jungle – Multiphase is the solution.

MV

-

Standard applications

Internal Separation

< 95% GVF

Differential pressure up to 50 bar

300# rating

Up to 5500 m3/h

From 50 m3/h

-

Cost Savings

Reduce CAPEX & OPEX

Sooner returns on Investment.

Production Increase

Increased and Prolonged Production

Increased Recovery

Positive environmental impact

“Zero-Flaring”

Technology Advantages

Enhanced production control

MPC

-

Wet Gas application

Internal Separation

98% GVF

Differential pressures up to 100 bar

900# rating

Up to 5500 m3/h

From 50 m3/h

MPC HD

-

High pressure application

External recirculation

99.5% GVF

Differential pressures up to 150 bar

900# (2500#) rating

Up to 2500 m3/h

Smaller footprint as standard MPC

-

Cost Savings

Reduce CAPEX & OPEX

Sooner returns on Investment.

Production Increase

Increased and Prolonged Production

Increased Recovery

Positive environmental impact

“Zero-Flaring”

Technology Advantages

Enhanced production control

MPC HC

-

High-capacity application

External recirculation

99.5% GVF

Differential pressures up to 50 bar

600# rating

Up to 7000 m3/h

Smaller footprint as standard MPC

Bornemann Pumps are the ideal Solution in Food Production and Pharma

-

SLH Twin Screw Pumps are rotating positive displacement pumps, using two screws to convey the product along the screw axis. The contact-free intermeshing screws and the housing form closed chambers, constantly moving product from suction to discharge. By right turn of the drive shaft, the flow direction goes from the front axial to the mid top position. The pump can operate in the oposite direction as well. Reverse operation is possible to empty the suction piping from product before cleaning

-

Pumping and cleaning processes with one pump

Low shearing to the pumped fluid, gentle handling

Minimal maintenance, reduction in cleaning pumps and pipes

Saves space through this 2 in 1 technology

-

Chemicals

Beverage Industry

Dairy Industry

Convenience

Sweets

Meat products

Food & Pharma

Cosmetics

Learn more about the company: