Bepex

Bepex International develops, designs, delivers and supports custom continuous processing systems for the food, mineral, chemical, and polymer markets.

Solid Handling

Thermal processing operations and technology by Bepex includes everything from continuous flash drying a high moisture organic wet cake to long residence time vessels to meet PPM final product moisture requirements. Each of our thermal process systems go beyond solids drying. Each system can carry out several operations, including cooling, heating, reacting, devolatilization, and crystallizing.

THIN-LAYER INDUSTRIAL PADDLE DRYERS | SOLIDAIRE

-

High-efficiency thin layer paddle drayer use for drying, reacting, crystallizing and devolation

INDUSTRIAL DISC DRYERS | TORUSDISC

-

Bed type indirect paddle dryer for drying, reacting, crystallizing, and heating / cooling.

INDUSTRIAL SCREW PRESSES | S-PRESS

-

Continuous mechanical liquid-solid separating press.

INDUSTRIAL DISC DRYERS | TORUSDISC

-

Flash dryer suitable for drying high-moisture slurries, pastes, and wet cakes.

STATIONARY CONTINUOUS FLUID BED DRYERS | FLUID BED

-

Stationery fluidized bed dryer for highly controlled, gentle drying, reacting, cooling or curing.

HOT AIR HOPPER DRYERS | PURGE VESSEL

-

Long residence time hopper dryer for near complete VOC removal.

HEATED SCREW CONVEYOR | THERMASCREW

-

Gentle agitation thermal screw conveyor for heating / cooling, cooking, roasting and drying.

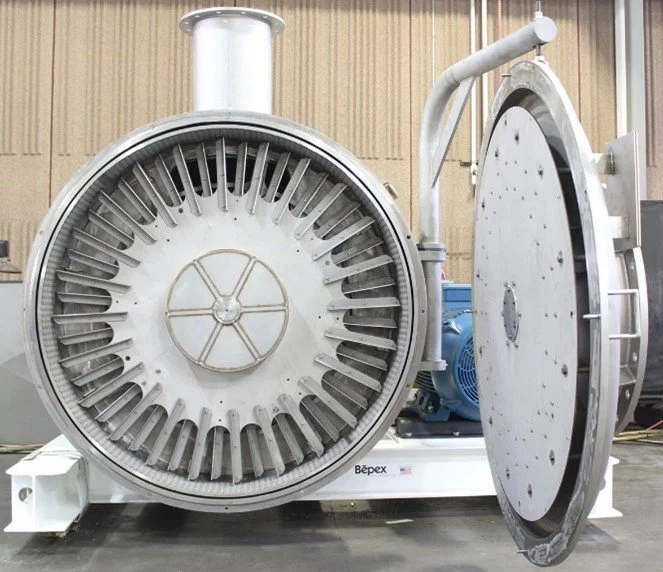

AGITATED VACUUM DRYER | CONTINUATOR

-

Agitated bed dryer used for pressure cooking, vacuum reaction, or long residence time devolatilization.

Size reduction processing equipment by Bepex includes everything from air classifying mills for fine grinding to large bale reducers, wet mills, and granulation equipment. Our diverse portfolio of size reduction products means we can better fit your needs, rather than trying to fit your needs into a single technology. Each of our size reduction technologies is available in our Process Development Center for testing, proof of concept, optimizing, or custom toll processing.

SIZE REDUCTION PROCESS

AIR CLASSIFYING MILL | PULVOCRON

-

Air Classifying mill utilizing high-speed impact and internal classification for fine grinding solids.

SANITARY FOOD PULVERIZER | EXTRUCTOR BLOCK GRINDER

-

Sanitary grinder to reduce large blocks prior to downsteam cooking, blending, or grinding.

INLINE WET GRINDER | RI DISINTEGRATOR

-

Inline wet mill for grinding and delumping slurries and pastes in pipeline applications.

ANGLED HAMMER MILL | RP DISINTEGRATOR

-

Sanitary angled hammer mill for grinding, delumping, pureeing and homogenizing.

RUBBER CHOPPER | RUBBER GRINDING EQUIPMENT

-

Sanitary grinder to reduce bales of natural and synthetic rubber ahead of dissolution, blending, and compounding.

HEAVY DUTY HAMMER MILL | RD DISINTEGRATOR

-

Heavy-duty hammer mill with secondary tramp meterail seperation.

DRY GRANULATOR EQUIPMENT | GRANULATOR

-

Compact hammer mill for grinding dry solids to a consistent particle size.

Our most common agglomeration processes are designed to enact a final particle specification, whether it’s shape, density, or dispersion qualities. Our base of knowledge provides a strong foundation for developing an agglomeration system to best fit your process needs. Utilizing both wet (binder addition) or dry (pressure) agglomeration, we are able to offer a variety of operations to best suit your processing needs.

AGGLOMERATION & MIXING PROCESSES

TWIN-ROTOR PADDLE MIXER | HYDRAMIX

-

Twin-rotor padle mixer suited for controlled reactions and solids hydration.

HIGH SHEAR INDUSTRIAL PADDLE MIXER | TURBULIZER

-

High-shear paddle mixer for wet agglomeration, granulation, mixing, and coating.

HIGH PRESSURE ROLL COMPACTOR

-

High pressure roll compactor for densifying, briquetting, and granulating fine solids.

TURBOFLEX

-

High-speed vetical paddle mixer to produce consistent, highly-dispersible granules.

FLEXTURBULIZER

-

Self-cleaning flexible chamer paddle mixer for agglomeration of cohesive materials.

LOW PRESSURE EXTRUSION | EXTRUD-O-MIX

-

Low-pressure extruder for continuous mixing and extrusion of solids and liquids.